A PAIR OF WORDS

about us

The measure of a perfect surface

and the way to get there - is us. You know exactly what quality your product should have in terms of function, design, appearance, utility value. The surface plays a decisive role here.

With our PVD coatings under the label deQoline® we meet the diverse requirements and high expectations that customers have of surfaces. Our solutions are not only wear-resistant and corrosion-resistant, but also adhesive, easy to clean, biocompatible, brilliant and colorful. You can rely on deQoline® for a surface that meets the highest standards and shows off your product to its best advantage.

Many years of extensive experience and excellent know-how form the basis for being able to fulfill such wishes individually and competently. As contract coaters, we have mastered a widevariety of processes and have developed specific coating systems to give your products - whether they are made of stainless steel, hard metal, brass, aluminum or ... that perfect surface that gives them an enormous increase in value, high gloss or an impressive color effect.

This is the small but decisive advantage that others will envy you for.

An overview

of our services

PVD

Extremely thin metal coatings characterized by high hardness, chemical resistance and aesthetics.

Electroplating

Electroplating to increase corrosion resistance (chromium, nickel, copper, zinc). Ideal pre-treatment for PVD coating.

Stainless steel blackening

Blackening process for ferrous base metals (including stainless steel) resulting in improved corrosion protection.

Further

PVD and electroplating, mechanical processing (brushing, polishing, grinding, sandblasting), anodic oxidation and surface analysis.

Industries

Medicine

PVD coatings are an ideal solution for a wide range of medical applications due to their biocompatibility, chemical stability and excellent mechanical properties.

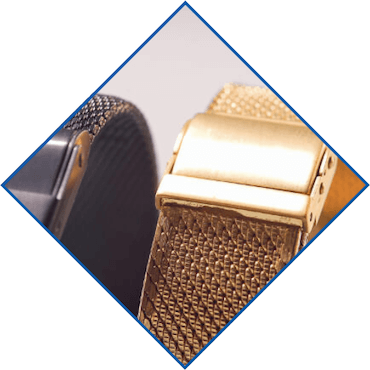

Decorative

A wide range of available and durable colors, ranging from the deepest black to the most authentic gold, are just one of the reasons why PVD coatings are widely used in the decorative industry.

Maritime

Excellent corrosion resistance is one of the main reasons why PVD coatings are a surface treatment of choice in wet environments.

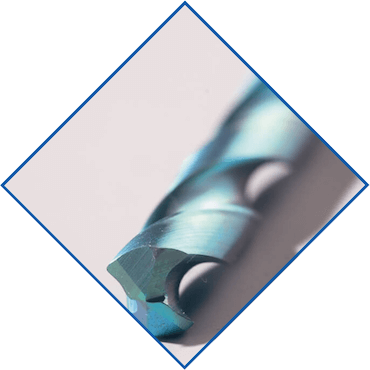

Tools

The durability of PVD-coated tools is ensured by extreme hardness, temperature stability and low coefficient of friction.

deQoline®

The development and manufacture of special coating systems using PVD vacuum technologies is our core competence under the deQoline® label.